|

Enervent energy recovery units are based on regenerative heat recovery. This is achieved with a rotating heat recovery wheel. The rotary wheel is built up of thin aluminium foil with small D-shaped air channels. |

|

Energy saving ventilation - efficiency up to 85 %! |

|

Enervent energy recovery units are based on regenerative heat recovery. This is achieved with a rotating heat recovery wheel. The rotary wheel is built up of thin aluminium foil with small D-shaped air channels. |

|

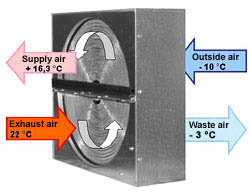

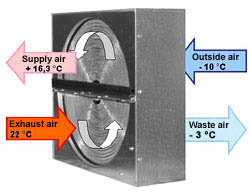

Rotating heat recovery wheelIn the ventilation unit a rotating wheel is used to warm up the cold outside air before it is taken inside the building. The heat exchanger absorbs heat from the exhaust air and with this warms up the cold outside air. The wheel has to rotate between these two airflows to achieve heat transfer. The rotary heat exchanger is the most efficient and cost saving way

of recovering energy during winter. In the warm weather cold is recovered

with the same high efficiency. The rotating wheel can operate in lower outside air temperatures without freezing than other types of heat exchangers. With a rotating heat exchanger we are able to balance the humidity inside the house in the winter on a healthy level between 35 -50 %, because the wheel also recovers some of the humidity on the supply and exhaust air volumes. All Enervent ventilation units are constructed for use throughout the year. Additional heating is seldom needed because the efficiency is as high as 85 %. Along with providing good indoor air quality, Enervent units save more heating energy than most other heat recovery units - all thanks to the high through the year efficiency. |

| [main page] |